After knurling, it can increase the sense of beauty of the part and make it easy to handle. It is often used for the outer surface processing of casing, hinge wrench and other parts

learn moreSecondary Operation Service

Over 20 different kinds of surface finishes for you.Make your part more corrosion resistant and aesthetical.

LML's Portfolio of Secondary Operation

KNURLING

CHAMFERING

It enhances the appearance and durability of edges by creating a beveled or chamfered edge on a surface. It is commonly used in various industries, such as manufacturing, architecture, and interior design, to create a clean and finish

learn more

GRINDING

Grinding is a process that smooths and polishes surfaces by removing small amounts of material through the use of abrasive stones or sandpaper. Grinding can be done by hand or with machines, and it is an essential tool for many trades and crafts.

learn more

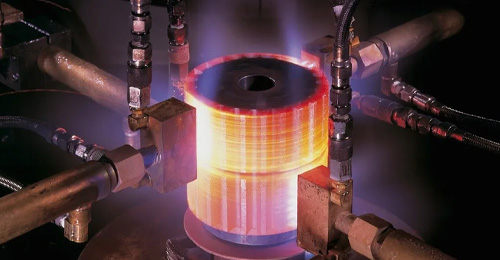

HEAT TREATMENT

Heat treatment alters the physical and mechanical properties by heating them to a specific temperature and then cooling them at a controlled rate, improving the strength, hardness, and corrosion resistance of metal parts.

learn more

WELDING

Welding is a process that joins two or more metal components by melting and fusing them together using heat and pressure. It requires skill and precision to ensure a strong and reliable joint.

learn more

RIVETING

Riveting is a process that joins two metal components securely by inserting a rivet through aligned holes and crimping its ends. It creates a strong and reliable joint. Riveting requires precision and skill to ensure a secure and reliable connection.

learn moreRelated Products

Functional

There is no necessary to have aesthetic look.Machining veins will be seen

- Smooth machining

- Passivation

- TYPE III andozied

- Glossing

- Brushing

- Black oxide

- Mechanical Polishing

- Etching

- Degreasing

- Electroplating

- Electrophoresis deposition

Matte

slogan:Removes surface streaks and defects, make surface matt and rough

- Blasting

- Acid pickling

- Passivation

- Parkerising

Functional

There is no necessary to have aesthetic look.Machining veins will be seen

- Chemical or electrochemical polishing

- Blasting+Anodizing

- Glossing+Brushing

- Glossing+Polish

- Powder coating

Wide Array of Services We Offer

Competitive Prices

You are guaranteed 30% lower costs and competitive prices to help you settle your material and start your project.

Reliable supply chain

Apart from self-owned factory, we have thousands of suppliers to maintain a stable supply of materials.

Superior Quality

Each of our material bears certified material certification to guarantee excellent quality for your parts.

Professional Support

Creative engineers and technicians are happy to help and recommend the suitable material for you.

Introduction to the Common Process of CNC Metal Materials

Metal CNC Services

LML provides the most advanced CNC metalworking services to ensure superior product quality and fast delivery. We have more than 60 metal milling machines and metal lathes that we can offer with the capacity and competitive prices. We accept small orders for CNC metal parts with a MOQ of 1 and can handle more complex CNC machining work, while we accept urgent orders. With LML, you can get the perfect products and thoughtful service you want, we are your friends in China.

Metal Machining

Metal machining is the process of cutting down a raw piece of metal to create a desired shape or object. This process is done most accurately with a CNC (Computerized Numerical Control) machine, which can produce almost any three dimensional object designed via CAD (Computer Aided Design) software. Our network of machinists mainly uses 3- and 5- axis CNC machines for producing any metal parts that pass our online DFM checks. State-of-the-art metal CNC machines, like the ones we use, are able to cut complicated features on parts with great accuracy, while maintaining tight tolerances.

Metal CNC Milling

CNC milling removes materials from the workpiece to create custom-designed parts with flat surface using cutting tool or multi-point milling cutters.

WIth our 3-axis & 5-axis CNC milling services, you can get milled parts with tight tolerance up to 0.02mm (±0.0008 in.)

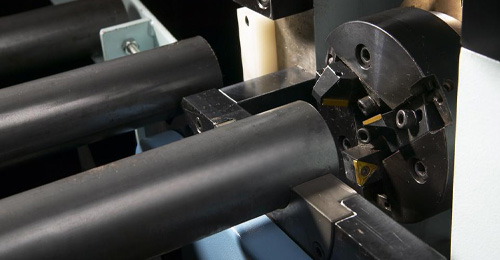

Metal CNC Turning

CNC turning shears materials from the ouside of a rod at incredible speeds using a spinning tool. At RapidDirect, we apply 50+ CNC lathes and CNC turning centers to create round or cylindrical turned parts with extreme precision that consistantly meet customers’ expectations.be higher.

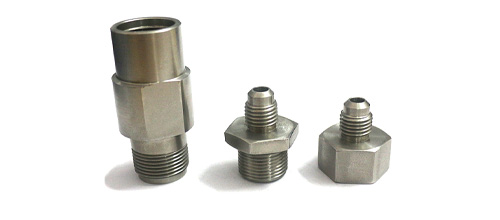

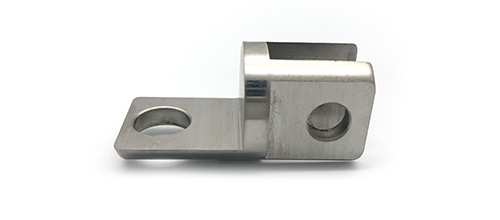

Gallery of Second Operation Parts Made by LML

The metal part can serve as functional or aesthetic purpose,and the way of usage will decide on the type of surface finish.

You Might Also Be Interested In

- How do I find a cnc machining supplier in chinaAug 5,2021How do I find a cnc machining supplier in china

FAQs

- Why 5-Axis CNC Machining Has Superior Advatages?"5-Axis" generally refers to the ability of a CNC machine to move the tool in five directions, which belongs to a high precision production technology.

- GALLERY OF CNC MACHINED PARTSGALLERY OF CNC MACHINED PARTS

- Could I have a look at your production facility for sliver contacts?Cold Heading & Stamping Workshop

Get your free quote now

Take advantage of our network and see what Xometry can do for you