Non-comestic

There is no necessary to have aesthetic look. Machining veins will be seen primarily.

Over 20 different kinds of surface finishes for you.

Make your part more corrosion resistant and aesthetical.

*All uploads are secure and confidential

| Finish | Service | Applicable to | Machining marks | Comestic availability | Tolerance | |

|---|---|---|---|---|---|---|

| Smooth Machining | CNC machining, sheet metal fabrication | Metals, Plastics | Clean and smooth without burrs | CNC machining | Tolerance are not affected |

| Polishing | CNC machining | Mild steel, aluminum, stainless steel | Remove the veins of the metal surface | Always comestic | Met after polishing |

| Brushing | CNC machining, sheet metal fabrication | Metals | Surface defects are partially removed | On request | Met after brushing |

| Shot Blasting | CNC machining, sheet metal fabrication | Metals | Removes surface streaks and defects | On request | Tolerance are not affected |

| Powder Coating | CNC machining, sheet metal fabrication | Metals, carbon fiber | Metal defects will be totally hiden | No | Met after coating |

| Spray Painting | CNC machining, sheet metal fabrication | Metals | Praying paint, pigment, or color to a solid surface as a colored protective layer | No | Met after painting |

| Black Oxide | CNC machining, sheet metal fabrication | Steel, copper, magnesium | Reduce the light reflection | No | Met before powder coating |

| Passivation | CNC machining | Aluminum, copper, stainless steel, titanium | Smooth and uniform surface | No | Tolerance are not affected |

| Parkerising | CNC machining | Metals | Pretreatment of painting to strengthen film adhesion | No | Tolerance are not affected |

| Anodizing | CNC machining, sheet metal fabrication | Aluminum、Magnesium、Titanium | Successful wear resistance surface finish technology of aluminum alloy | On request | Met after anodizing |

| Electroplating | CNC machining | Metals | Improve wear resistance, electrical conductivity, reflective property, corrosion resistance and aesthetics of the metal product | No | Met after electroplating |

| Electrophoresis Deposition | CNC machining | Metals | More environmentally friendly than other coating technique | No | Met after electrophresis deposition |

| Baking finish | CNC machining, sheet metal fabrication | Metals | Resistant to water, dust,grease and easy to clean | On request | Met after baking finish |

| Thermal spraying | CNC machining, sheet metal fabrication | Metals | As protective or functional surface layer | No | Tolerance are not affected |

| Physical vapor deposition | CNC machining, sheet metal fabrication | Metals | As protective or functional surface layer | No | Tolerance are not affected |

| Antirust oil for electrostatic spraying | Antirust oil for electrostatic spraying | Metals | Antirust | No | Tolerance are not affected |

| Cleaning services | CNC machining, sheet metal fabrication | Metals | Remove the carbonizing film and oil of the surface | No | Tolerance are not affected |

There is no necessary to have aesthetic look. Machining veins will be seen primarily.

Finishes can be either cosmetic or non-cosmetic as per request

These finishes will always serve a cosmetic function

You are guaranteed to enjoy a 30% reduction in costs and competitive prices, which will assist you in procuring your materials and initiating your project.

In addition to our own factory, we have a network of suppliers to ensure a consistent supply of materials.

Each of our material bears certified material certification to guarantee excellent quality for your parts.

Our team of innovative engineers and skilled technicians is eager to assist you and provide recommendations for the most suitable materials for your needs.

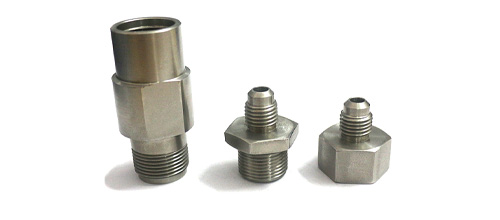

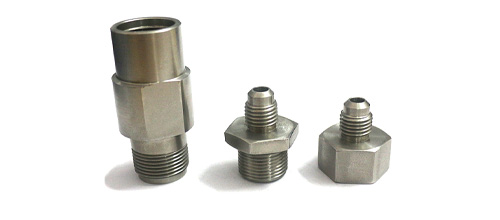

LML provides the most advanced CNC metalworking services to ensure superior product quality and fast delivery. We have more than 60 metal milling machines and metal lathes that we can offer with the capacity and competitive prices. We accept small orders for CNC metal parts with a MOQ of 1 and can handle more complex CNC machining work, while we accept urgent orders. With LML, you can get the perfect products and thoughtful service you want, we are your friends in China.

Metal machining is the process of cutting down a raw piece of metal to create a desired shape or object. This process is done most accurately with a CNC (Computerized Numerical Control) machine, which can produce almost any three dimensional object designed via CAD (Computer Aided Design) software. Our network of machinists mainly uses 3- and 5- axis CNC machines for producing any metal parts that pass our online DFM checks. State-of-the-art metal CNC machines, like the ones we use, are able to cut complicated features on parts with great accuracy, while maintaining tight tolerances.

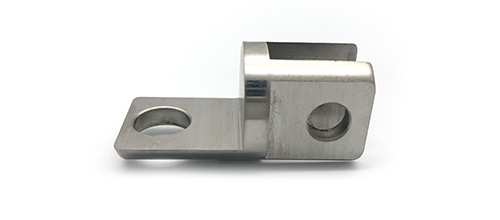

CNC milling removes materials from the workpiece to create custom-designed parts with flat surface using cutting tool or multi-point milling cutters.

WIth our 3-axis & 5-axis CNC milling services, you can get milled parts with tight tolerance up to 0.02mm (±0.0008 in.)

CNC turning shears materials from the ouside of a rod at incredible speeds using a spinning tool. At Rapid Direct, we apply 50+ CNC lathes and CNC turning centers to create round or cylindrical turned parts with extreme precision that consistantly meet customers’ expectations.be higher.

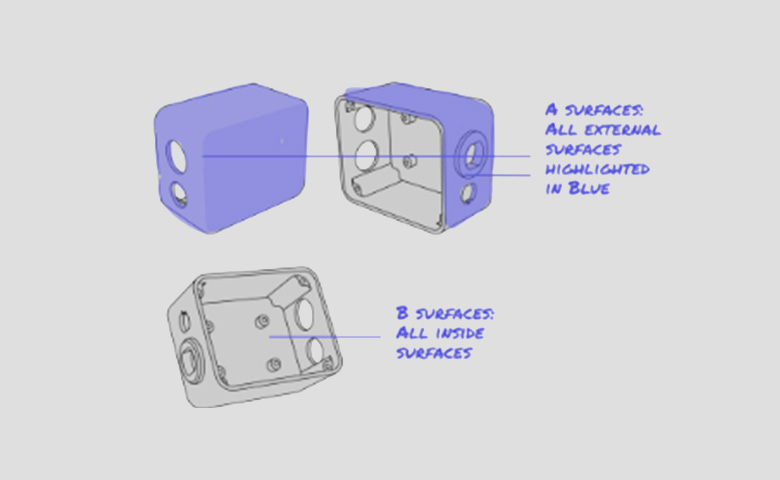

Surface finishing often leaves aesthetic defects on your parts, such as hang marks for anodizing. Defining an Aand a B-side in your design will ensure that the most important areas of your part remain free of defects

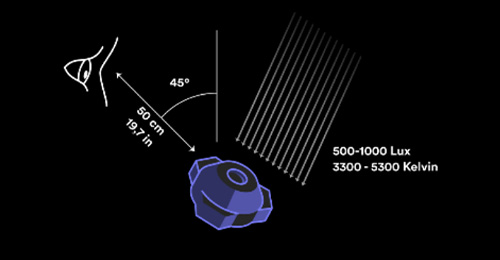

In this image you can see how you can define an A-side and a B-side in your technical drawing:

A side: Indicates the most aesthetically importantsurface, typically the visible side of your product.

B side: Indicates the side that is not aesthetically important, typically the side hidden from visibility after assembly

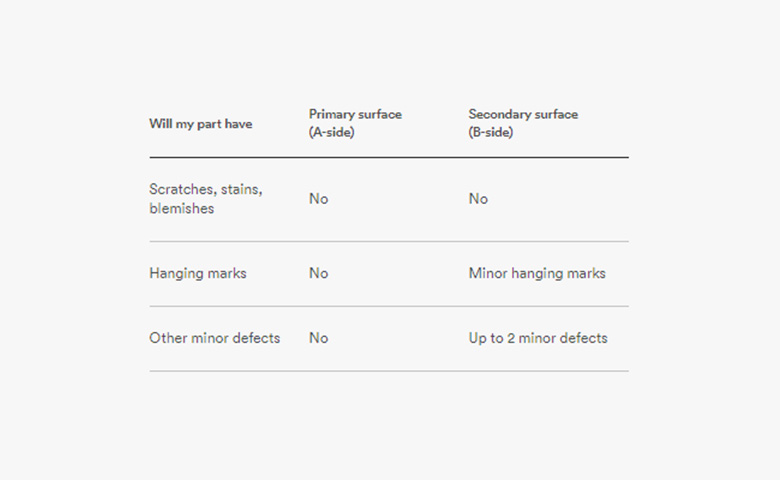

For the primary surface (A-side) of your part, we guaranteedefect-free production. In contrast, secondary surfaces (B-side)may be machined with hanging marks and other minor defects. Bside surfaces, like the rest of your part, will be free of scratches.stains and blemishes.

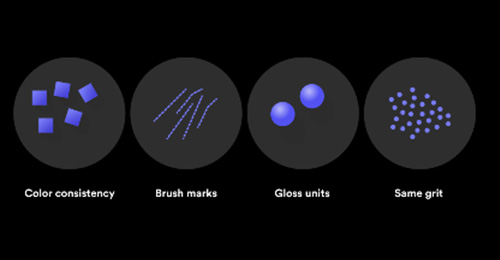

Each part must be visually consistent across the same batch.meaning:

* Manual brushing marks will be as unidirectional aspossible. Please note that for rounded geometries, brushingmarks may not be entirely unidirectional.*

The surface quality of every part must meet the followingconditions:

Take advantage of our network and see what LML can do for you